|

|

|

|

Archived News Fuel Pressure Regulators for EFI applications

With the variety of fuel injection systems available, it is important that we understand that fuel pressure regulators are only one link in the chain for ensuring the correct amount of fuel is supplied for the combustion process. Can you feel the pressure? On a conventional EFI system, the sole purpose for the FPR is to maintain fuel pressure at a constant differential to manifold vacuum under all engine load conditions. This type utilises vacuum from the inlet manifold allowing it to totally control the ‘set” fuel pressure. Any modifications to this type of FPR will have affects on other engine management systems, such as:

Turn it up! BEWARE – Increasing the fuel pressure will reduce fuel pump flow. A suitable fuel pump must be used to suit the operating pressures and flows required or major engine damage will occur eventually. Common FPR Faults As stated earlier the FPR is only one link in the chain for fuel control. A conventional EFI system with fuel rail mounted FPR can be visually checked for any abnormalities such as:

BE AWARE - Fine foreign particles trapped in the fuel rail is a common cause of gradual fuel pressure build up causing excessive rich mixtures over prolonged driving and of course excess fuel consumption. It is therefore important that the fuel rail be flushed when replacing any FPR Returnless Fuel Systems – The Point of No Return! This fuel system generally locates the Fuel Pressure Regulator (FPR) in the fuel tank and is integrated as part of the fuel module (Fuel Pump Assembly). With no vacuum connection to the inlet manifold, this eliminates the “fuel rail pressure” and the “manifold pressure” relationship, with necessary allowances now made during injection duration programming.

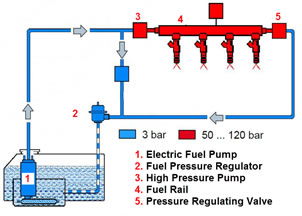

With the development of the direct injection EFI system with extremely high operating pressures, (created by a mechanical fuel pump assembly) various means of regulating this pressure were introduced to suit the varying engine loads and driving conditions, for both the supply and the main fuel rail circuits. Supply to the main pump

Fuel Rail Regulation Pulse Width Modulated (PWM) control of the pressure regulating valve by an ECU allows for increase/ decrease of fuel rail pressure / flow

|

Archived News

Understanding EGR Systems (Pt 1) |

| privacy statement terms of use terms and conditions sitemap news |  |

These are just a few, but now imagine an adjustable type FPR fitted to amodified vehicle and the importance of the correct pressureadjustment for the expected engine operation and performance.

These are just a few, but now imagine an adjustable type FPR fitted to amodified vehicle and the importance of the correct pressureadjustment for the expected engine operation and performance. This is important when the same engine is available as turbo and non turbo productions as they vary. The actual pressure testing requires test equipment and confirmation that the fuel pump supply is adequate before condemning any FPR.

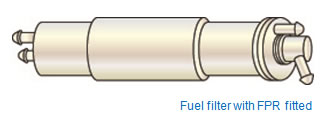

This is important when the same engine is available as turbo and non turbo productions as they vary. The actual pressure testing requires test equipment and confirmation that the fuel pump supply is adequate before condemning any FPR. Variations to this system may be found where the FPR is part of the fuel filter and is mounted external of the fuel tank, allowing a vacuum source to the inlet manifold and a return for the excess fuel back to the fuel tank.

Variations to this system may be found where the FPR is part of the fuel filter and is mounted external of the fuel tank, allowing a vacuum source to the inlet manifold and a return for the excess fuel back to the fuel tank. A conventional FPR in the supply circuit as shown and/or Pulse Width Modulated (PWM) control of the electric in tank fuel pump. i.e. Electrically pulsing the voltage to the fuel pump at various widths as required for the load conditions.

A conventional FPR in the supply circuit as shown and/or Pulse Width Modulated (PWM) control of the electric in tank fuel pump. i.e. Electrically pulsing the voltage to the fuel pump at various widths as required for the load conditions.