|

|

|

|

Archived News What's all this noise about fuel pumps?

Fuel for thought

Pump it Up We all know that modern fuel pumps are manufactured all over the world and to different standards, but at the end of the day the fuel pump is expected to supply the correct fuel flow and maintain the correct fuel pressure requirements for all modes of vehicle operation, and do it quietly and efficiently. When this is not achieved we have to carry out tests, figure out what went wrong and look at the reasons why. Once the swearing has stopped, it comes down to a few causes. Firstly it is a “Fuel” Pump not a dirt or water or rust or air pump, you need a clean supply of fuel. Simply, if this is the cause of the fuel pump becoming noisy or failing, then it makes no difference what type or where it was manufactured, it is still going to fail. The fuel pump motor speed can be as high as 10,000 RPM and the pumping element clearance down to microns on a quality pump. The technician’s job of course, is to ensure that the fuel tank and lines are clear of all contaminants that cause so much grief, especially when they expect a warranty replacement for a seized fuel pump caused by foreign particles. A free replacement doesn’t usually happen! Let the blame game commence Now for the dreaded fuel pump problems that DO NOT include foreign contaminants

Seriously, the fuel pump is a commonly replaced component, especially during the hot summer months and in some cases it is replaced unnecessarily, because it’s easier to blame the fuel pump before any testing has been carried out. Yes! The thought is - It feels like a fuel pump fault I’ve done before – “Just replace it!” Testing Times Nobody likes it, but once all the testing has been carried out and yes, it’s definitely the fuel pump causing grief, and then it’s time to work out why? It’s the time where the cheaper fuel pump is now – “Not so cheap” – and you wonder if you should have gone for the “reputable brand” instead, and not believe some of the misleading advertising you may have read about some of the lower cost pumps. Many of these manufacturers will claim they have the equivalent, or even improved the products, but the truth is they are generally made using lower grade materials, or have used other cost saving measures, with the result being a lower quality part. Although some form of testing is often claimed by these suppliers, it is the independence and integrity of such testing claims that must be substantiated to assure product equality. In most cases the benefit of the lower price is far outweighed by its major disadvantage - it's often an inferior product, which means they suffer in terms of fit, accuracy, robustness and durability, and end up costing much more in the end in avoidable repairs, and more importantly your reputation. The times they are a changing

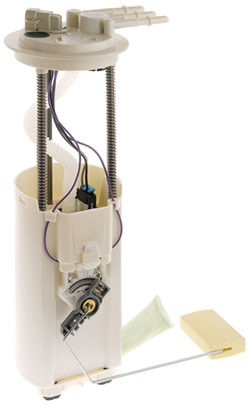

As technology has evolved complexity has been further enhanced by fuel delivery modules which are an assembly that includes an electric fuel pump, sound isolation units, all the mounting gear (flange, wiring harness), and a fuel level sensor, pressure regulator and fuel run out device. A typical fuel pump module may combine:

It is important that the replacement is the “correct” quality module; otherwise you have just wasted a lot of time and money. CHECK before you fit! No matter which way you like to sugar coat it, outside of foreign particles, the inferior quality of the module purchased is the main cause of any pre-mature failure or problem. Here we go again It’s not necessarily the “Here we go again” phone call to the parts supplier for a warranty claim, but the wasted time it takes to remove and replace the faulty pump that hurts the most and if the quality is questionable “Its cross your fingers and hope for the best” – again! Here is a little tip If you are going to renew a fuel pump module on a vehicle fitted with a plastic tank, leave the old pump module attached to the tank until it’s time to replace. If the module has been removed for a long period of time, the fuel tank can warp in that area and makes it difficult to refit the new unit. They may look the same, but all parts are not created equal. Delphi, one of the world’s largest auto components suppliers, supply quality fuel pumps and modules that deliver fast-pressure rise for quick engine starts and feature internal springs, an integrated OE fuel vapour pressure sensor and two-strainer system for long-lasting durability. What does that mean? Reliable fuel pumps you, and your customers, can trust. One of the most significant factors to consider is who stands behind the product you buy or sell? Some companies supply products that they claim offer the functionality and performance of the quality brand product, but without the support and peace of mind the leading global developers and manufacturers such as Delphi, Bosch, Pierburg, VDO and Denso can offer, is it worth the risk? It’s what’s underneath that sets quality brands apart It’s often what cannot be seen that makes the quality product the right decision. If we look at a Delphi Fuel Module for example, it features:

So why specify the brand name next time you need to supply a fuel pump or assembly? High quality, extended reliability, reduced noise, and lower return rates that help get the job done right, fast, the first time, that’s why! |

Archived News

Understanding EGR Systems (Pt 1) |

| privacy statement terms of use terms and conditions sitemap news |  |

Let’s get one thing straight, a quality fuel pump assembly that a technician has just fitted to a vehicle for which it was designed and manufactured, should give the same service as a fuel pump fitted to a new vehicle straight from the showroom – No More, No Less! If that is not the case – Why not? After all that is what the paying customer expects.

Let’s get one thing straight, a quality fuel pump assembly that a technician has just fitted to a vehicle for which it was designed and manufactured, should give the same service as a fuel pump fitted to a new vehicle straight from the showroom – No More, No Less! If that is not the case – Why not? After all that is what the paying customer expects. The current trend is to replace the complete fuel pump assembly (module) to eliminate any (common) fuel line leakage that may be created during the pump installation or any electrical connection problems. (It's also a hell of a lot quicker!). BEWARE – The fuel pump modules may vary in the number of internal components to suit various makes and models – sometimes even within the same model. The N16 Nissan Pulsar is a fine example.

The current trend is to replace the complete fuel pump assembly (module) to eliminate any (common) fuel line leakage that may be created during the pump installation or any electrical connection problems. (It's also a hell of a lot quicker!). BEWARE – The fuel pump modules may vary in the number of internal components to suit various makes and models – sometimes even within the same model. The N16 Nissan Pulsar is a fine example.