|

|

|

|

Archived News Idle Speed Control - Don't stand idle?

The automotive fuel injection system has gone through

many changes since it was first introduced many years

ago. One of the areas that has transformed from a basic

mechanically operated heat controlled to a fully electric

motorised control operation is the engine idle speed

monitoring and operating system.

IAC – Idle Air Control T  his is a widely used system in the industry and its

characteristics are common on most vehicles. These

include: his is a widely used system in the industry and its

characteristics are common on most vehicles. These

include:

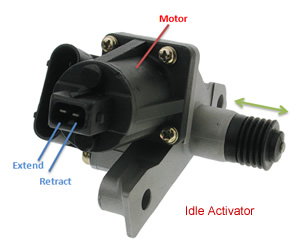

IDLE Actuator System  This system is ECU controlled and physically operates

the throttle valve – even though it was used on a few

earlier models it is not an extremely common unit.

Common characteristics include: This system is ECU controlled and physically operates

the throttle valve – even though it was used on a few

earlier models it is not an extremely common unit.

Common characteristics include:

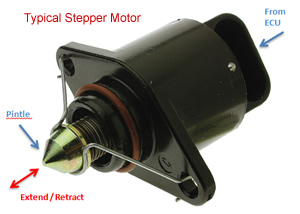

Typical Stepper Motor Operation This is a commonly used system found in vehicles from all corners of the world. An example of this ECU controlled system is the common GM type stepper motor. The ECU operates this unit in small steps starting from zero where the pintle has extended and completely closed the air by pass. The ECU will then operate the stepper motor up to 255 steps, fully retracting the pintle. The desired stepper motor position for "idle" is based on:

A typical VX Commodore 6 Cyl ECU stepper motor hot

idle reading is approximately 25 steps. If the steps are

excessive this would indicate a dirty throttle body or

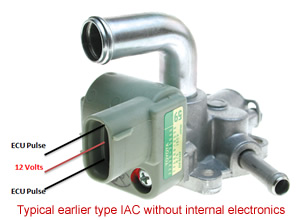

Typical earlier type IAC without internal electronics

Typical mid 2000 later IAC with internal electronics

Idle Activator

similar causing the ECU to retract the pintle to

compensate and allow more air. Note: Disconnecting the

harness plug will lock the pintle into that position until

reconnected. A typical VX Commodore 6 Cyl ECU stepper motor hot

idle reading is approximately 25 steps. If the steps are

excessive this would indicate a dirty throttle body or

Typical earlier type IAC without internal electronics

Typical mid 2000 later IAC with internal electronics

Idle Activator

similar causing the ECU to retract the pintle to

compensate and allow more air. Note: Disconnecting the

harness plug will lock the pintle into that position until

reconnected.Stepper Motor Assembly integrated with AAV  Many stepper motor assemblies incorporate 4 winding

phases that are controlled by the ECU and a coolant

temperature controlled wax pellet type AAV for total idle

air control. e.g. N16 Nissan Pulsar and a variety of

Mitsubishi vehicles. Many stepper motor assemblies incorporate 4 winding

phases that are controlled by the ECU and a coolant

temperature controlled wax pellet type AAV for total idle

air control. e.g. N16 Nissan Pulsar and a variety of

Mitsubishi vehicles.The ECU generally operates 2 windings in sequence to alter air quantity. The mechanical AAV allows for air by pass when the engine coolant is cool and reduces this air by-pass as the engine heats up. Common faults with this system

It is important when dealing with all these systems to understand that there are external factors affecting their operation. e.g. Vacuum leaks. The base idle settings are also important to ensuring a smooth deceleration to idle operation. Vehicle stalling is common when the base idle is incorrectly set. In many cases a manufacturer's procedure (e.g. bridging electrical connections) must be performed to ensure the correct positioning of the IAC motor / pintle, prior to any adjustments being carried out at the throttle body. |

Archived News

Understanding EGR Systems (Pt 1) |

| privacy statement terms of use terms and conditions sitemap news |  |

Idle speed high or low due to IAC valve sticking or internal electrical fault

Idle speed high or low due to IAC valve sticking or internal electrical fault