|

|

|

|

Latest News Ignition Distributors Over the past years the common automotive vehicle ignition system has evolved from a points ignition distributor to the current distributor less Coil-over-plug system. Even though the Coil-over-plug system has been fitted to vehicles for a while now, a large percentage of vehicles still on the road are fitted with distributors utilising electronic ignition principals and still requiring diagnosis, testing, repair or replacement. What the Technician Needs to know about the Electronic Ignition distributors:

Common faults and testing procedures. Testing procedures and test equipment vary depending on the type of distributor fitted to the vehicle and the type of fault that has occurred. Typical test equipment used

Areas to investigate when a low or no spark condition is evident;

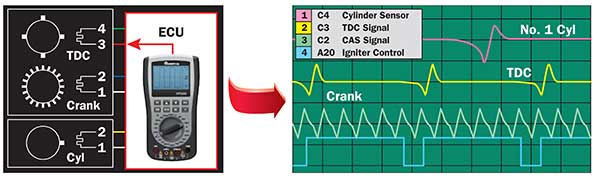

Typical Example of Testing. (Honda) Honda distributor with three internal inductive pick-up-coils and an internal ignition module and ignition coil. Method: Using a suitable Oscilloscope and back probing the 3 sensors. A Multimeter may be used for testing static voltage supply for ignition module and ignition coil.

Checking signal strength for:

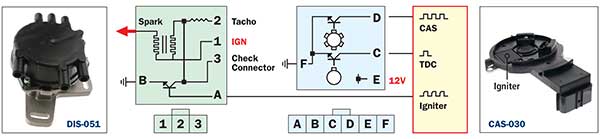

All these signals are monitored by the ECU for Spark and injection timing and control. If all signals are acceptable, the ECU should trigger the distributor ignition module which intern switches the ignition coil ON and OFF to create the HT spark which is distributed to the relevant cylinders as required. Typical Example of testing a distributor with integrated dual HALL sensor and power transistor. (Mazda V6) Method: Using a suitable Oscilloscope and back probing the HALL sensor signals and ECU trigger for the power transistor / igniter. A Multimeter may be used for testing static voltage supply for all power supplies for Ignition coil and HALL sensors.

Note: A common “no spark condition” may be caused by a power transistor/ Igniter (integrated in the HALL sensor assembly) failure. Checking the signal from the ECU to “Terminal A“ whilst cranking, will quickly allow the Technician to rule out a variety of possibilities. A suitable pulse at this point indicates that the CAS signals are functioning, and the ECU is switching the igniter as required. A suitable signal at the TACHO terminal indicates that the igniter is switching ON and OFF and further attention is required to the Ignition coil. No signal at the TACHO terminal indicates that there generally is a failure in the power transistor/Igniter. Again, depending on the condition and age of the distributor, it may be more economically viable to replace rather than to repair the complete unit. There are of course many other distributor configurations, but these typical test procedures should allow the Technician to quickly determine the next plan for attack. The Premier Auto Trade Ignition Distributors (DIS) program now includes almost 150 part numbers covering 1 million vehicle applications in Australia and NZ.

|

Latest News

Tech Tips - Wheel Speed Sensors (WSS) |

| privacy statement terms of use terms and conditions sitemap news |  |