|

|

|

|

Latest News Performance Regulators and Gauges What Technicians need to know about performance Fuel Pressure Regulators and related Fuel Gauges when upgrading a vehicle’s fuel supply system for performance applications. A standard Fuel Pressure Regulator (FPR) valve configured and fitted to a standard fuel system on an engine can control the required fuel pressure for all driving conditions as well as releasing any return fuel flow back to the fuel tank. Retaining residual fuel pressure in the fuel pressure lines when the engine has been switched OFF is also an important feature of the pressure regulator valve that may cause difficult re -starting conditions if this feature fails. For more details on FPR operation, please refer to our Fuel Pressure Regulators overview. When a fuel system “supply” upgrade is to be carried out to compensate for mechanical and other modifications for performance increases, it is essential that the fuel pressure regulator can withstand the greater fuel flow from the new upgraded fuel pump. An FPR that restricts the higher fuel flow alters the pressure control function of the FPR unit as well as increasing the load on the new fuel pump and modifying system fuel flow. That is: A suitable FPR is used to maintain steady fuel supply, even during dramatic changes in fuel demand. The correct fuel pressure must be used to ensure the necessary air/fuel mixture is correctly maintained to ensure maximum performance is achieved. Over Increasing the fuel pressure does not necessarily increase the expected engine power output through the RPM range. Typical adjustable FPR units used in the Performance industry, suitable for upgrades of up to 1000HP. Note: there are 2 intake ports and a return to tank port.

Typical features of a performance Fuel Pressure Regulators:

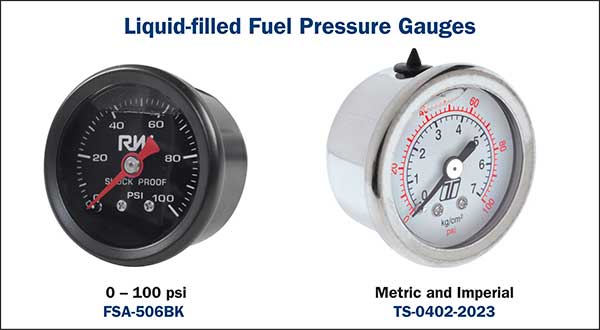

Rising Rate FPR Further Increasing fuel supply for forced induction applications (if required) during boost only to increase the required fuel supply, can be achieved and recommended by PCM tuning. In some cases, a Rising Rate FPR may be utilised for a similar affect without PCM altering. Where the conventional FPR is 1:1 rated, the rising rate units may be typically rated at 1.5:1 or 1.7:1 for common systems or 1.95:1 for higher boost systems. This results in a higher fuel pressure during boost compared to the conventional 1:1 rated FPR units. Liquid filled Fuel Pressure Gauges Monitoring fuel pressure during low and high engine loads allows for quick and accurate diagnostics during a potential low engine power condition. Mechanical fuel gauges are commonly used as a low cost but fairly accurate means of checking pressures. Altering the fuel pressure to a required value becomes an easy task by monitoring the pressure gauge as the adjustment is being performed. The use of fluid in the gauge dampens the engine vibrations for a more accurate pressure monitoring as well as dampening the needle vibration to assist in visual pressure identification. These gauges may be either imperial or metric rated or combined.

Note: These gauges may be located in the engine bay BUT must not be located near a direct heat source. Premier Auto Trade offer an enormous range of over 200 Performance Adjustable Fuel Pressure Regulators from the world's leading brands including Turbosmart, Fuelab, Raceworks, SARD and Holley. Suitable for applications requiring a fuel system that supports up to 3000HP, for use with various fuels including Gasoline, Ethanol and Methanol. There are 5 Fuel Pressure gauges to complement the range, available in both Liquid-Filled and Non-Liquid Filled. Premier Auto Trade distributes products throughout Australia via a network of specialised resellers and leading automotive groups. |

Latest News

Tech Tips - Wheel Speed Sensors (WSS) |

| privacy statement terms of use terms and conditions sitemap news |  |