Latest News

Relay problems on vehicle

What a Technician needs to know when dealing with electrical relay problems on vehicles.

A faulty vehicle relay or circuit may create an intermittent fault or a continuous hard fault no matter what circuit it may operate. The relay types and configurations were covered in detail in the previous relay article but the effect of a failing or failed relay in a circuit may cause an array of potential results that may become problematic for the technician to diagnose.

A typical example is the common fuel pump relay or circuit that may:

- Intermittently not function

- Totally not function

- Electrically or physically cause relay to permanently remain on.

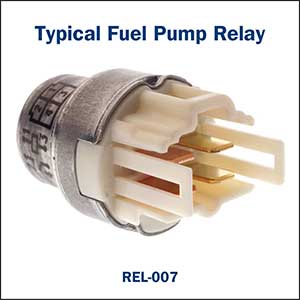

Any one of the fuel pump relay or circuit fault conditions can be common on many vehicle types with the repair requirements generally ranging from a simple task of removing and renewing a replaceable push-in relay , testing and repairing circuit harness wiring or renewing a failed PCM.

Simple relay replacement

There are of course variations to “the simple fuel pump relay replacement” process on some vehicles. These vehicles require extra time to rectify the condition and, in many cases, requires thorough investigation prior to any repair quotation.

A typical example is:

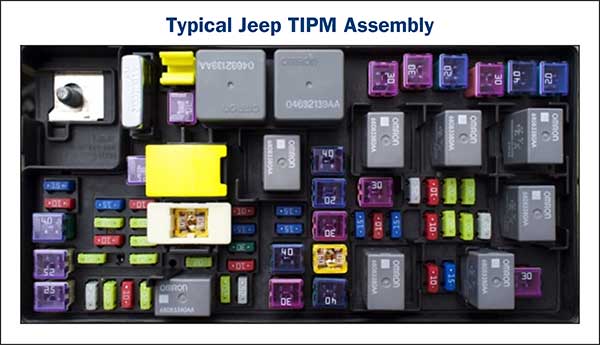

Chrysler, Jeep, Dodge vehicles fitted with a “TIPM” assembly (Totally Integrated Power Module) located in the engine bay that incorporates an array of fuses and relays.

Even though the fuel pump relay is generally (originally) located in the TIPM assembly, it may not be externally visible. Common typical faults on these vehicles that require access to the fuel pump relay for testing.

Vehicle continuously winds over and will not start.

Note - The stop button generally requires activating to cancel the cranking process if Start/Stop button is fitted. This may start out as an intermittent fault but may generally become more common over a period of time and will eventually leave the driver stranded.

Battery continuously loses charge after engine switched off.

Note - Fuel pump relay contacts that remain closed after the engine has been switched off may cause the fuel pump to continuously operate and drain the battery.

Unfortunately, the fuel pump relay is not quickly accessible for easy removal from the TIPM which results in extended labour work time, but the technician must ensure that the relay is not continuously energised “electrically” which may cause the relay closed condition, prior to the TIPM assembly removal. This can be tested with a suitable scanner. A visible fuel pump fuse is accessible to isolate the fuel pump if required for test purposes.

Faulty relay replacement options on these vehicles for a technician to consider.

Note: a manufacturer recall to modify the fuel pump relay may have been previously carried out on the vehicle which positions a relay and socket connector externally of the TIPM. This simple replacement procedure takes minimal time to rectify the faulty relay condition.

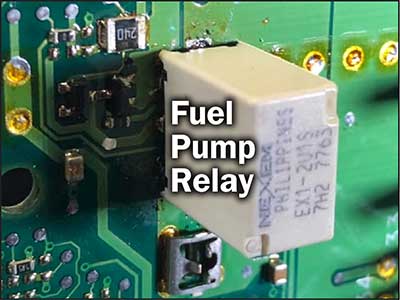

Original relay fitted to the TIPM assembly.

There are generally 3 options to rectify the relay fault condition on an original Fitted relay in a TIPM.

- Replacing the TIPM assembly, even though an option, is not a common one due to cost.

- Dismantling the TIPM assembly and renewing the fuel pump relay is labour intensive and requires care when re soldering the relay on the circuit board.

- The most common replacement option is the external placement of the fuel pump relay that by-passes the original relay. (if not already carried out by manufacturer during recall)

The Premier Auto Trade Sensor range includes over 70 Relays (REL) from the world’s leading manufacturers, covering almost 10 million vehicle applications in Australia and NZ.

When you supply and fit products from Premier Auto Trade you can expect a product designed and tested to the vehicle manufacturer’s specifications offering OE form, fit and function. Premier Auto Trade distributes products throughout Australia via a network of specialised resellers and leading automotive groups. |