Latest

News

Testing EGR Systems (Exhaust Gas Recirculation) - Pt 2

September 2012

With the variety of EGR systems used for the control of

NOx emissions it is important to understand the

components operation, prior to carrying out any diagnostic

or testing. (Refer to previous issues for EGR system

operation).

Testing times for EGR systems

A defective component in the EGR system may have a

very detrimental effect to the engine performance and

therefore the emissions.

Strict emission laws and the malfunction indicator light

generally illuminated when a system fault exists, require a

prompt resolution.

1. Pneumatic EGR Valve System Component Tests

Note that vacuum supply to all components must be tested

on the vehicle to eliminate misdiagnosis

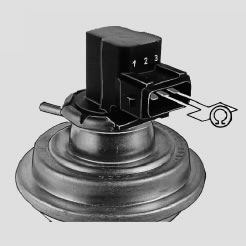

Single diaphragm type EGR valve

Using a manual vacuum hand pump can verify movement

of the valve and the condition of the diaphragm. This can

be performed on or off the vehicle. Dual diaphragm types

will vary in test procedure.

EGR valve with potentiometer feed back

Potentiometer resistance can be checked with the harness

disconnected. Voltage test is preferred with the harness

connected using a suitable scanner / scope or multimeter.

Electro-Pneumatic Vacuum Pump Valve

Using the vacuum pump can verify if the valve is sealed or

leaking when not activated and if the valve opens when the

solenoid is activated. Solenoid resistance can also be

tested with an ohm meter.

Thermo Valve

Using the vacuum pump can verify if the valve is closed

when cold and heating the unit with a heat gun should

result in the valve opening above approximately 70

degrees Celsius.

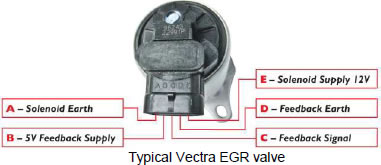

2. Electric EGR Valve Test

The combination EGR valve and feedback system in this

unit is controlled and monitored by the ECM and requires

no external vacuum source to operate.

Note: This is a typical vehicle pin out configuration but this

can vary for different vehicle models. Always refer to

correct wiring diagram.

A suitable scanner can assist in testing this type of EGR

valve by using the scanner program to activate the solenoid

and also monitoring the feedback signal. The switching of a

functioning valve can be audible when the engine is not

running.

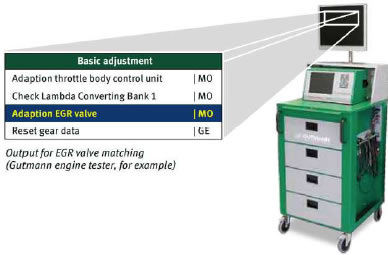

On later vehicles, renewing the EGR valve requires relearning

by using program options in the scanner. That is

the electric EGR valve must be adapted to the ECU.

Tips for troubleshooting EGR – Its Exhausting!

The most common cause of malfunctions in the EGR

systems are stuck or blocked EGR valves due to excess

carbon build up. This generally results in incorrect sealing

between the exhaust and inlet and results in idling

problems and poor performance.

In most cases the EGR valve is replaced but the cause of

the excess carbon is not investigated, why?

Engine Management systems where an Intake Air

Temperature (IAT) sensor is located directly in the inlet

manifold can assist greatly is diagnosing leaking EGR

valves.

That is, monitoring the IAT output signal from a cold start –

idling condition, should not indicate rapid increase in intake

air temperature.

This would be the case if the EGR valve was allowing

exhaust gas to enter the inlet manifold when not required.

|