|

|

|

|

Latest News Oil Level and Oil Temperature Sensors Operation What Technicians need to know about “Oil Level” (OLS) and “Oil Temperature” Sensor (OTS) types and operation to assist in the individual stand alone or combination sensor units and related circuit diagnosis and testing. Oil level sensors have been utilised by most imported and now discontinued local vehicles for many years. Early vehicles only monitored low engine oil levels with the use of a switch attached to a float. A light or message in the instrument cluster would warn the driver if the oil level was low but only when the engine was not running. (Static monitoring).

Testing this simple ON/OFF switch generally does not create a problem due to its simplicity. Engines that use thicker engine oils (high viscosity) may in some cases create sludge and varnish build up which generally affect this type of sensor operation dramatically and must be taken into consideration during testing. This type of sensor is therefore utilised more on engines that use thinner (low viscosity) engine oils. Later oil level sensors generally vary the means of operation to ensure that both static and dynamic (engine running) oil levels are monitored for greater accuracy and preventing potential engine failure if oil is lost during driving conditions. Generally, three possible causes for low oil alarm that results in the driver being warned.

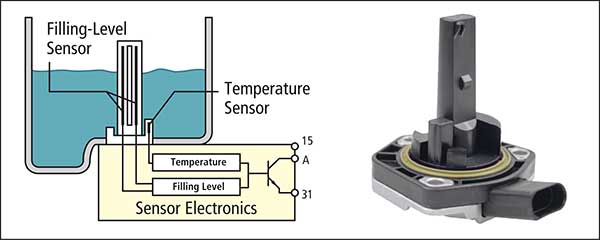

Some sensors use an electrical resistance method whereas less of the sensor is covered by engine oil, the resistance value of the sensor changes. Newer more accurate ultrasonic oil level sensors utilise a piezoelectric transducer which sends ultrasonic pulses into the engine oil and receives echoes from the engine oil surface back to the sensor. This information is monitored by the PCM and together with the engine speed, engine oil temperature and possibly driving attitude data from the ABS system is used to determine the dynamic oil level.

The PCM can then alert the driver to add more engine oil if low.

On some applications:

Note: On BMW E39 (5 Series) with M52 engine and BMW E46 (3 Series) Vehicle performing conditions:

Possibly created by a faulty oil level switch that may cause fuse 15 or fuse 30 to blow so there is loss of input to the EWS (BMW security module) from the transmission range switch. Oil Temperature Sensors. (OTS) As discussed in the previous oil temp sensor article, the engine oil may be monitored with the use of a standalone OTS or combination oil level sensor (OLS) and oil temp sensor (OTS). The OTS receives a reference voltage (usually 5V) from the PCM. The other terminal is generally connected to a floating ground. The internal resistance will vary in relation to engine oil temperature.

Typical location of combination sensors on an oil sump.

These OTS sensors are widely used on both petrol and Diesel applications. A Typical OTS sensor function for petrol engine:

A Typical OTS sensor function for Diesel engines:

Typical symptoms of a failed OTS unit or circuit:

Testing procedures for both stand alone and combination sensors are covered in detail in the previous OTS article. The Premier Auto Trade Sensors range includes 16 Oil Level and Temperature Sensors (OLS / OTS) from the world’s leading manufacturers, covering almost 800,000 vehicle applications in Australia and NZ. When you supply and fit products from Premier Auto Trade you can expect a product designed and tested to the vehicle manufacturer’s specifications offering OE form, fit and function. Premier Auto Trade distributes products throughout Australia via a network of specialised resellers and leading automotive groups. |

Latest News

Tech Tips - Wheel Speed Sensors (WSS) |

| privacy statement terms of use terms and conditions sitemap news |  |