|

|

|

|

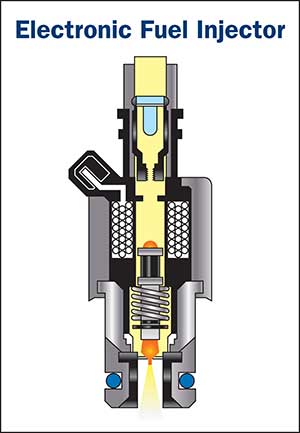

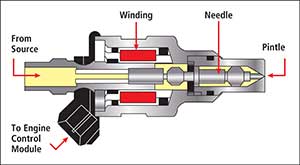

Latest News Performance Fuel Injectors What Technicians need to know when dealing with Fuel Injector suitability for performance applications. Due to the variations in fuel injector types and characteristics, it is important for the Technician to clearly understand the “basic operation” of the fuel injector prior to researching any replacement units for performance applications. Even though the basic operation does not alter on performance injectors, the characteristics can dramatically change as the fuel pressure, operating method and injector design varies. Simplified: What happens inside an injector when it is energised?An electromagnet moves a plunger that opens the valve, allowing the pressurised fuel to exit through a tiny nozzle. This nozzle is designed to atomize the fuel prior to entering the intake manifold or combustion chamber.

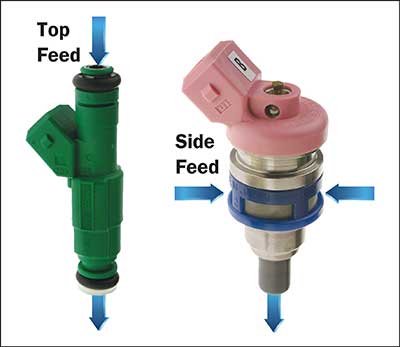

Injectors may be of the “Top Feed type” or “Side Feed type” for Performance and standard applications.

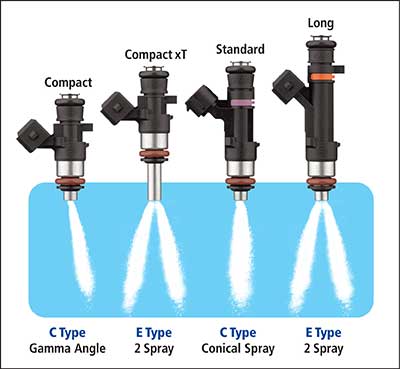

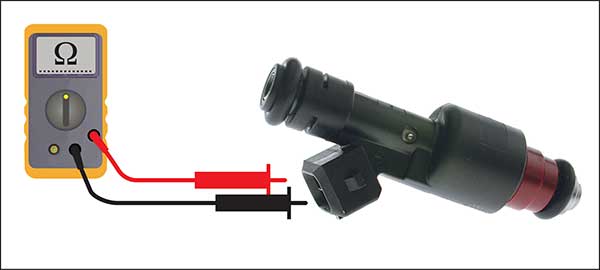

Top Feed injectors: As the name suggests, the fuel feeds into the injector from the top. Side Feed injectors: The fuel enters through slots machined into the sides of the injector. This has great injector cooling characteristics but there are limits to this type of injector usage for performance applications. Why do some modifications require changing side feed systems to top feed? Generally, side feed injectors are size limited (Typically, approx.1000cc), the top feed injectors generally have a cost advantage when changing to larger injectors. Top feed injectors allow for a greater variety of fuel flow ranges that exceeds the side feed The top feed injector system generally retains a more stable operating fuel pressure with the top feed fuel rail characteristics also allowing for a greater unrestricted fuel flow. Operating Principals SimplifiedWhat is “Fuel Injector Duty Cycle” An injector on a running engine is continually switched “ON” and switched “OFF” by the PCM. The period that the injector is switched ON during that cycle (and allowing fuel to be Injected) is classified as Duty Cycle and is calculated as a percentage. That is: a 50% duty cycle indicates that the injector is being switched ON and OFF for the equal amount of time. A greater duty cycle increases the injector ON time. What is “Injector Pulse Width” This simply refers to the amount of time measured in milliseconds (ms) that an injector stays open generally during the intake cycle. (delivers fuel) Injector pulse width for an idle condition at normal operating temp may be typically: 2.5-3.5ms. This will increase as engine load increases. Typical “Injector Spray Pattern Varieties” Not all injector spray patterns are alike. Injectors are designed to supply the correct amount of fuel directed to an area as required by the manufacturer. Altering the spray pattern may affect the performance dramatically. Typical Bosch spray pattern variations What are the effects of “Increasing the Standard Fuel Pressure”? Increasing the fuel pressure will of course increase fuel flow up to a limit. Unfortunately, when the system fuel pressure is increased, the fuel pump flow decreases. If the system fuel pressure is increased dramatically, without upgrading the fuel pump, What is the difference between “Low Impedance” and “High Impedance” injectors? The majority of injectors are high impedance (saturated) with a typical winding resistance of Between 10 and 14 Ohms.

Low Impedance injectors (Peak and Hold) generally have a resistance of between 2 and 4 Ohms. Note: Low impedance and High Impedance injectors cannot be interchanged without modification to the Injector drivers. Reduced Engine performance and possible injector driver damage may result. Fuel flow through an injector Fuel injector flow rates are generally expressed as “cubic centimetre per minute” (cc/m) or Pounds per hour (Mass in lb/hr) at a certain fuel pressure. Given the same pressure, 1 lb/hr = 10.5cc/min. In some cases, Injector flow rates are expressed in millimetres per minute (mm/min.) Note: Adding higher flow injectors without any engine or system modifications will not create extra horsepower. The larger the flow rate, the more horsepower they are able to support. Larger injectors are only required when you have exceeded the horsepower capacity of the existing fuel injectors. What PSI are fuel injectors rated at? The term “across the injector” takes manifold pressure and fuel rail pressure into account and is usually referred to as “Delta Pressure”. Ford Performance’s fuel injectors are always rated as 39.15 psi delta. Injector sizingFuel injectors are generally replaced for 2 reasons:

When purchasing higher flow injectors to complement engine modifications, it is essential to ensure that the injectors are compatible with the engine/ system and ensure the flow rate will conservatively cover the increased power goals. Note: Most injector companies recommend keeping maximum injector duty cycle at 80%. As a result of engine upgrades, a revised tune is generally required, so it is advised to upgrade to a higher injector flow rate. Flow matched sets. Fuel flow rate may vary from injector to injector and installing non matched injectors with varying flow rates may result in sub optimal performance. The flow matched injector set generally reduces the variations dramatically (As low as 1%) allowing for optimum engine performance. Determining injector flow rate: A formula that was used for many years to determine flow rate requirements for fuel injectors was typically: (HP / # injectors) x (BSFC / Duty cycle) = Flow Rate That is: (Horsepower / number of injectors) x (Brake Specific Fuel Consumption / Inj Duty cycle) = To determine the best injector flow rate. Example only: Formula: (345/8) x (.5/.8) =26.95lb/hr Note: Actual BSFC for an engine may be difficult to accurately access. Injector Body Styles:

Fuel Injector Adapters Increases the range of suitable injector flow rates.

PAT offer over 50 Performance Fuel Injectors from the world’s leading brands including Bosch, Siemens, Raceworks and Delphi. Suitable for applications requiring injectors that support between 40-470HP per injector, for use with various fuels including Gasoline, Ethanol, Methanol and Compressed Natural Gas. Premier Auto Trade distributes products throughout Australia via a network of specialised resellers and leading automotive groups. |

Latest News

Tech Tips - Wheel Speed Sensors (WSS) |

| privacy statement terms of use terms and conditions sitemap news |  |