|

|

|

|

Latest News Knock Sensors What a technician needs to know about the types, the function, diagnosis and test methods of the common knock sensors. Knock sensor function: Motor vehicle manufacturers have been designing motor vehicles to comply with strict emission requirements for many years. We have seen leaner mixtures that are necessary to achieve some of the emission requirements. Unfortunately, with leaner mixtures also create the increased possibility of engine detonation or pinging as it is generally called The use of knock sensors as a sensitive monitor for engine vibrations created by detonation can allow an electrical return signal to the PCM to trigger an ignition retarding condition that can vary the amount of retard so that detonation is prevented, and the engine performance is not inhibited. They are generally located as close as possible to the combustion area where the detonation vibrations are best monitored. The number of sensors vary depending on the engine design, from a simple single unit on an inline engine to a now common 4 units fitted to a V engine Toyota/Lexus for more accurate monitoring. Unfortunately, many of these units are in “hard to get to“ places that make it time consuming for testing / diagnosing / replacing, so it is important that only correct quality units are fitted as replacements. Types of common Piezo Electric knock sensors that produces an AC voltage based on vibration or noise. Mass Piezo Electric type – Picks up noise in an entire range of frequencies – this may pick up engine mechanical noises. Resonance Piezo Electric (typically up to 1000Hz) – Picks up noise that relates to detonation frequencies. Filters engine and other mechanical noises. To minimise RF (radio frequency) noise affecting knock sensor operation, a shielded wire is generally utilised from the knock sensor to the PCM. This is generally on single wire sensors. The 2 wire knock sensors utilise the second wire as a shield and a signal ground reference.

Typical faulty knock sensor symptoms.

Typical causes of failure for knock sensor.

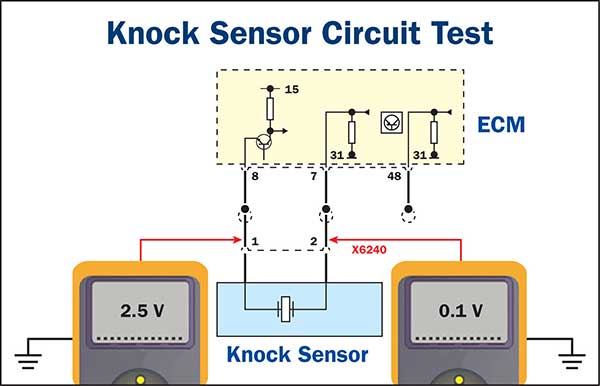

Typical knock sensor and circuit test with Multimeter.

Typical 2 wire knock sensor circuit with Bias Voltage – 2.5V with sensor connected. (other wire ground).

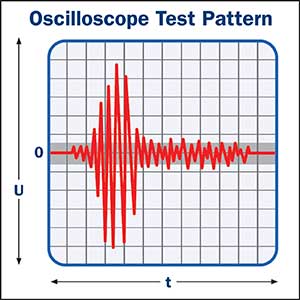

Typical knock sensor and circuit tests with suitable oscilloscope. Prior to connecting oscilloscope: Knock sensor and circuit specific typical fault codes.

The Premier Auto Trade Sensors range includes more than 85 Knock Sensors (KNS), covering over 8.5 million vehicle applications in Australia and NZ. When you supply and fit products from Premier Auto Trade you can expect a product designed and tested to the vehicle manufacturer’s specifications offering OE form, fit and function. Premier Auto Trade distributes products throughout Australia via a network of specialised resellers and leading automotive groups. |

Latest News

Tech Tips - Wheel Speed Sensors (WSS) |

| privacy statement terms of use terms and conditions sitemap news |  |