Latest News

Electronic Throttle Bodies

What the technicians need to know when diagnosing Electronic Throttle Body faults whilst the vehicle is in a “Reduced Engine Power” mode.

Many a throttle body has been unnecessarily renewed due to not correctly carrying out basic power supply and ground tests on the throttle bodies and related circuits that may indicate a simple fault that can be rectified without renewing the throttle body.

Typical example:

A vehicle with Diagnostic fault codes logged:

- P1682 Ignition switch circuit fault

- P0030 HO2S Heater control circuit

- P2101 TAC Motor circuit (throttle actuator control) range/performance

- and the vehicle locked in a “reduced engine power” mode will require thorough testing prior to any parts replacement.

What information does the Technician require prior to carrying out any tests?

- Has any work been previously carried out on the vehicle?

- Is there an electrical link between the O2 sensor heater circuit and the throttle body causing the O2 sensor code to be logged as well?

- Where does the power supply originate for the O2 sensor heater and the TBO control?

- Are all grounds acceptable at the TBO control and O2 sensor circuit?

- What conditions are required for the PCM to log the codes?

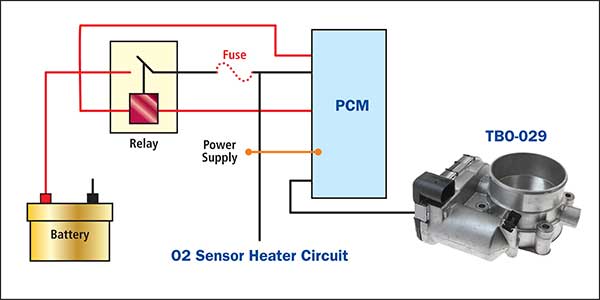

For this vehicle example, the fuse supplies power to both the Engine PCM (TBO circuit) as well as the O2 sensor heater circuit. All throttle body terminals are directly connected to the PCM so it is important that power supply to the PCM is acceptable.

Testing Procedure requirements : checking voltage supply readings at fuses / PCM or O2 sensor heater terminals must be carried out when the circuit is operating (electrically loaded).

Note: testing the voltage (with no electrical load) may indicate a near normal (or slightly lower) voltage reading on a circuit with a high resistance problematic point within the circuit. This may prevent the true condition to be disclosed causing incorrect diagnosis.

The PCM may generally utilise a separate ignition voltage supply that will create a Reduced Engine Power mode if the PCM detects a reduced voltage difference between the 2 circuits.

Cause of fault:

In this example, the relay supplying both the O2 sensor heater and the PCM was at fault creating a voltage drop that caused the PCM to activate the reduced engine power mode and logging the related fault codes. The O2 sensor heater was also supplied with a reduced voltage from the relay under load. (engine running).

Replacing the relay and cancelling the fault codes allowed the engine to perform normally on a road test.

Typical TBO fault codes that may be created by a faulty electronic TBO.

Codes P2111 and P2112 are common on throttle bodies on vehicles that have achieved high kilometres.

These fault codes will again cause the PCM to create a reduced engine power mode condition but for other reasons.

A typical example of this fault condition may be commonly found on a Chrysler throttle body.

Removing the TPS cover and investigating the intermediate gear may disclose damage to the gear assembly. Renewing the throttle body is the only option for this condition.

Codes P2111 & P2112 Chrysler 2.4 Electronic Throttle Body replacement.

Removing the TPS cover plate to carry out internal investigation of the TBO.

If the cover is to be removed from the TBO unit that is retained by spring loaded clips (typical GMH unit) it is important that the retaining clips are replaced in the correct order during reassembly.

It is advisable to ensure the intermediate gear is not removed, but if it must be removed that it is placed in the same original position. Note: The TPS drive points must be aligned correctly prior to reassembly to prevent any internal damage.

A typical manufacturers sequence procedure may be: (GM.)

After refitting the TBO to the vehicle, ensure the post fitting procedures are carried out to ensure customer satisfaction.

The Premier Auto Trade Emission range includes more than 130 Throttle Bodies (TBO), covering almost 6.5 million vehicle applications in Australia and NZ.

When you supply and fit products from Premier Auto Trade you can expect a product designed and tested to the vehicle manufacturer’s specifications offering OE form, fit and function. Premier Auto Trade distributes products throughout Australia via a network of specialised resellers and leading automotive groups. |