|

|

|

|

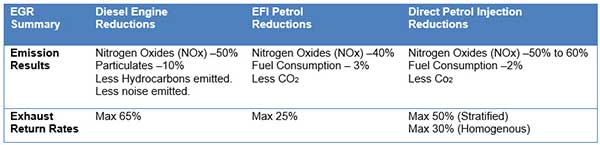

Latest News Exhaust Gas Recirculation Valves (EGR) What the Technician needs to know about testing a variety of EGR valves. When an EGR is fitted to a petrol or Diesel engine, we know that its main purpose is to limit the harmful and unwanted Oxides of Nitrogen (NOx) emissions that are produced due to high combustion temperatures in both types of engines. The EGR system is a method that has been used for a while and is still currently used to assist the vehicle manufacturers to build engines that pass strict Government enforced regulations. Typical EGR effect on Petrol and Diesel Engines

Testing a variety of EGR valve types. There are a few important issues we need to clarify prior to carrying out any testing of the EGR components or circuits.

Special test equipment that can test off-car is the PlusQuip EQP-115 Electronic EGR / Throttle Body and Actuator Tester. Refer to more information here

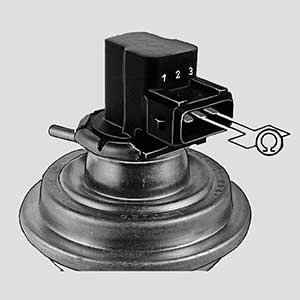

A defective component in the EGR system may have a very detrimental effect to the engine performance and therefore the emissions. Strict emission laws and the malfunction indicator light generally illuminated when a system fault exists, require a prompt resolution. 1. Pneumatic EGR Valve System Component Tests Note that vacuum supply to all components must be tested on the vehicle to eliminate misdiagnosis Single diaphragm type EGR valve

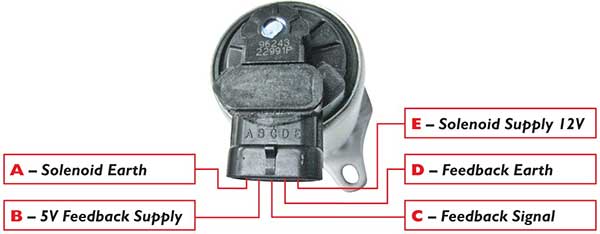

EGR Valve with potentiometer feedback

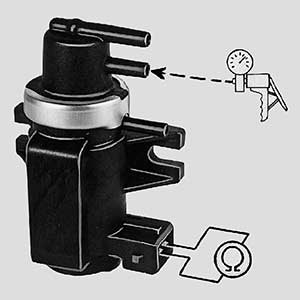

Electro-Pneumatic Vacuum pump valve

Thermo Valve

2. Electric EGR Valve Test The combination EGR valve and feedback system in this unit is controlled and monitored by the ECM and requires no external vacuum source to operate.

Note: This is a typical vehicle pin out configuration, but this can vary for different vehicle models. Always refer to correct wiring diagram. The EQP-115 tester is connected to the 2 outer terminals of this EGR valve. Altering the pulse width signal allows the valve to open and close as requested whilst current draw is monitored for accurate assessment. The position sensor is tested separately but must be tested during an open / close cycle. Electric EGR Valves with Cooler Modules

Ensure cooler is not restricted internally. Coolant leakage both internal and externally may become problematic and must be checked. DC Motor EGR Valve with Hall Sensor Response

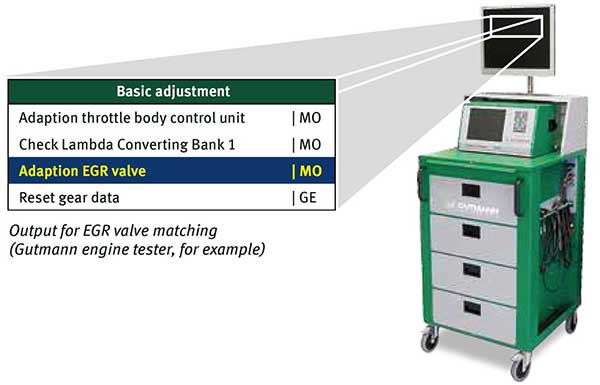

The Hall type position sensor varies in test procedure to the analogue type. Gear damage may become problematic on this unit due to excessive internal torque created by carbon build up. Note: A suitable scanner can also be used to test the electric EGR valve circuits by utilising the scanner program to activate the motor and monitoring the feedback signal (position sensor). On later vehicles, renewing the EGR valve requires relearning by using program options in the scanner. That is the electric EGR valve must be adapted to the ECU.

The Premier Auto Trade Emission range includes more than 100 Exhaust Gas Recirculation Valves, covering over 3.8 million vehicle applications in Australia and NZ. When you supply and fit products from Premier Auto Trade you can expect a product designed and tested to the vehicle manufacturer’s specifications offering OE form, fit and function. Premier Auto Trade distributes products throughout Australia via a network of specialised resellers and leading automotive groups. |

Latest News

Tech Tips - Wheel Speed Sensors (WSS) |

| privacy statement terms of use terms and conditions sitemap news |  |

.jpg)